The most common method for treating rising damp is to remove salt-contaminated plaster and then inject a silicone damp-proofing cream at regular intervals into holes drilled along a horizontal mortar course on the affected wall. On a successful treatment, the active silicone ingredient contained within the cream will spread through the mortar course and cure to form a waterproof barrier to damp. The wall is then replastered using a salt-resistant plaster or render.

The most common point of failure with this treatment method is the damp-proofing cream. If a damp-proofing cream with an insufficient amount of silicone active ingredient is used or an insufficient amount of cream has been injected, this waterproof barrier will not properly form and the damp will not be halted.

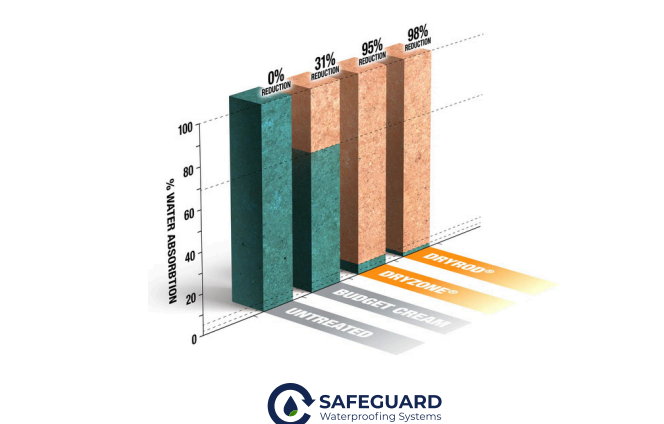

Low Strength or Insufficient Damp Proofing Cream Success depends heavily on the strength of the product. Dryzone Damp Proofing Cream contains over 60 percent active ingredient, which ensures deep penetration and a strong barrier.

Many weaker alternatives contain less than 15 percent active content. Independent tests show that these products fail to spread properly through the mortar, leaving the wall unprotected even if they carry certification.

Treatments often fail because of workmanship issues. Examples include injection holes not being fully filled or voids in the masonry diverting product away from the treatment line. In these cases, not enough active ingredient reaches the mortar course and the barrier does not form correctly.

For long-term reliability, Dryrod Damp Proofing Rods provide an advanced alternative. These fibre rods are pre-saturated with the correct amount of active ingredient and are inserted into drilled mortar holes.

When a rising damp treatment has failed, it is necessary to install a second damp-proof course treatment. If you are using damp-proofing creams, this treatment must take place on a separate mortar line to the original. Even though the first treatment was unsuccessful, the drill holes will have cured to stop the spread of the cream.

If, however, Dryrod is used to carry out the retreatment, the original drill holes can be used. The chemical formulation of the active ingredient contained within the rods is able to diffuse throughout the previously treated mortar course.

Contact Us 011 7083603

Email techncal@safeguardchem.co.za