Safeguard Chemicals, originally established in the UK in 1983, expanded its operations to South Africa by establishing a branch in 1997. Over time this branch evolved into Safeguard SA, a wholly owned South African company that focuses on manufacturing and distributing WATERPROOFING & DAMP PROOFING products for the construction industry.

Safeguard Chemicals is not only a significant player in the construction industry but also the first black woman-owned company in this field. Our emphasis on being “Women in Waterproofing“ highlights a unique perspective and approach that sets us apart.

The range of services and expertise offered by us includes:

Comprehensive Solutions: Our team of experts provides end-to-end solutions covering everything from the initial design stage to the actual execution of projects. This full-service approach streamlines projects and provides our clients with a seamless experience.

Diverse Applications: Our expertise covers a wide spectrum from below-ground solutions to roof waterproofing. This versatility ensures that our company can cater to various construction needs and challenges.

Project Scope: Whether it’s new construction, restorations or renovations Safeguards solutions are adaptable to different project types and scales.

Support: Our commitment to providing support both online and on-site is a significant advantage. This level of engagement enhances customer satisfaction and ensures the success of projects.

Root Cause Approach: Treating the cause rather than the symptoms is our commitment to delivering long-lasting and effective solutions. This can lead to higher client trust and repeat business for you.

Ethical and Unstoppable: The emphasis on us being ethical and unstoppable reflects our strong company culture and values that resonate well with clients and partners.

Experience: 25 years of experience demonstrates our established track record and reliability in providing solutions.

Safeguard offers a unique blend of expertise, dedication and values that truly differentiates us in the industry. Being women-owned and operated adds another layer of inspiration and empowerment to our story.

Safeguard Chemicals, originally established in the UK in 1983, expanded its operations to South Africa by establishing a branch in 1997. Over time this branch evolved into Safeguard SA, a wholly owned South African company that focuses on manufacturing and distributing WATERPROOFING & DAMP PROOFING products for the construction industry.

Safeguard Chemicals is not only a significant player in the construction industry but also the first black woman-owned company in this field. Our emphasis on being “Women in Waterproofing“ highlights a unique perspective and approach that sets us apart.

The range of services and expertise offered by us includes:

Comprehensive Solutions: Our team of experts provides end-to-end solutions covering everything from the initial design stage to the actual execution of projects. This full-service approach streamlines projects and provides our clients with a seamless experience.

Diverse Applications: Our expertise covers a wide spectrum from below-ground solutions to roof waterproofing. This versatility ensures that our company can cater to various construction needs and challenges.

Project Scope: Whether it’s new construction, restorations or renovations Safeguards solutions are adaptable to different project types and scales.

Support: Our commitment to providing support both online and on-site is a significant advantage. This level of engagement enhances customer satisfaction and ensures the success of projects.

Root Cause Approach: Treating the cause rather than the symptoms is our commitment to delivering long-lasting and effective solutions. This can lead to higher client trust and repeat business for you.

Ethical and Unstoppable: The emphasis on us being ethical and unstoppable reflects our strong company culture and values that resonate well with clients and partners.

Experience: 25 years of experience demonstrates our established track record and reliability in providing solutions.

Safeguard offers a unique blend of expertise, dedication and values that truly differentiates us in the industry. Being women-owned and operated adds another layer of inspiration and empowerment to our story.

Phil Llewellyn’s dual role as the Technical Director of Safeguard Waterproofing Systems and Chairman of DWASA, combined with over 20 years of experience in inspecting sites and handling legal cases makes him one of the most knowledgeable and well-rounded professionals in the field of damp proofing and waterproofing in Southern Africa. If you find yourself in need of an experienced representative for legal matters related to this specialized area, Phil Llewellyn could be a valuable resource to consider for guidance and support. Be sure to contact him for more information and assistance.

When searching for a damp assessor make sure to inquire about their qualifications and experience. Ask if they have the necessary certifications, training, and experience in dealing with damp issues.

Remember that a thorough and professional damp inspection can help identify the extent and causes of damp issues in your property which can be crucial for addressing and resolving the problem effectively.

Phil Llewellyn’s dual role as the Technical Director of Safeguard Waterproofing Systems and Chairman of DWASA, combined with over 20 years of experience in inspecting sites and handling legal cases makes him one of the most knowledgeable and well-rounded professionals in the field of damp proofing and waterproofing in Southern Africa. If you find yourself in need of an experienced representative for legal matters related to this specialized area, Phil Llewellyn could be a valuable resource to consider for guidance and support. Be sure to contact him for more information and assistance.

When searching for a damp assessor make sure to inquire about their qualifications and experience. Ask if they have the necessary certifications, training, and experience in dealing with damp issues.

Remember that a thorough and professional damp inspection can help identify the extent and causes of damp issues in your property which can be crucial for addressing and resolving the problem effectively.

Our technology has been tried & tested in over 80 countries worldwide. From residential to industrial, below ground to roof, internal to external, wet & dry, old & new, we provide you with Simple Solutions for Complex Waterproofing.

Product knowledge is essential to the successful use and specification of the products that we sell. Therefore, we make product information easily available and provide you with full product support throughout your projects.

Our technology has been tried & tested in over 80 countries worldwide. From residential to industrial, below ground to roof, internal to external, wet & dry, old & new, we provide you with Simple Solutions for Complex Waterproofing.

Product knowledge is essential to the successful use and specification of the products that we sell. Therefore, we make product information easily available and provide you with full product support throughout your projects.

PRODUCT GUARANTEE

Polyurethane Roofing – SG PU280

Polyurethane Foundation – SG PU610

Joint Sealant – SG Flex20

Bitumen Roofing – 4mm Torch-on membrane

Polyurethane Undertile Showers / Balconies – SG PU610

Cementitious Undertile Showers/Balconies – Latseal Slurry

Polyurethane Roofing – SG PU280

Polyurethane Foundation – SG PU610

Joint Sealant – SG Flex20

Bitumen Roofing – 4mm Torch-on membrane

Polyurethane Undertile Showers / Balconies – SG PU280

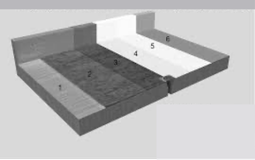

Waterproofing of roofs, basements, etc. shall be laid under appropriate manufacturer guarantees supplemented

by a contractor workmanship guarantee. Waterproofing to flat roofs shall be laid with a minimum fall to outlets of

1:80 and include all outlets, etc.Waterproof of external basment walls shall take into account the definition of dry and wet sides as per SANS 10021: 2006 6.15.2 and 6.1.5.3 and provide one or two layer membrane systems as

appropriate descriptions of sheets or membrane waterproofing shall be deemed to include all labour costs.

Apply Safeguard SG720″ primer to prepared surfaces, followed by two coats of “Safeguard SG280” waterproofing

polyurethane and one coat of SG PU440 with SG PU Fabric on horizontal and vertical joints.

Apply Safeguard SG720″ primer to prepared surfaces, followed by two coats of “Safeguard SG280” waterproofing

polyurethane and one coat of SG PU450 with SG PU Fabric on horizontal and vertical joints.

Thoroughly clean and prepare all external walls from foundation to 2 brick courses above finished ground level as per Safeguard Method Statement for Surface Preparation.

Apply one coat of Safeguard SG 720 Primer to the walls by spray, roller or brush and allow to dry.

Apply two coats of Safeguard SG PU 610 by spray, roller or brush. If applying by spray, dilute with 5% MEK. Allow the first coat to dry overnight. A third coat should be applied where “Wet” sites are encountered as per SANS 10021:2006 6.1.5.3

Protect membrane with soft board or dimpled membrane prior to backfill.

Equivalent performance-related products may be supplied.

Thoroughly clean and prepare all external walls from foundation to 2 brick courses above finished ground level, removing all dirt, dust, grime grease and any unnecessary mortar,

Apply one coat of Polyurethane Primer to the walls and allow to dry.

Apply two coats of Polyurethane waterproofing membrane to a DFT of 1-2mm. The membrane should accommodate temperatures from -30? to +90?C and have a minimum elasticity of 600% with a Shore A hardness of 60 or greater and a Tensile strength of 4N/mm? or greater. Allow the first coat to dry overnight. A third coat should be applied where “Wet” sites are encountered as per SANS 10021:2006 6.1.5.3

Protect membrane with soft board or dimpled membrane prior to backfill.

Thoroughly clean and prepare the surface, as per Safeguard Method Statement for Surface Preparation.

Apply one coat of Safeguard solvent-based Bitumen Primer to the surface ensuring full coverage without any “ponding” of primer on the surface.

Allow to dry and heat-fuse one layer of Safeguard Euro Gecko 4mm APP single re-inforced Bitumen Membrane to the primed surface, lapping all side walls and dressing into and around outlets and upstands.

Provide 100mm side laps and 150mm end laps to adjoining rolls of membrane, ensuring that laps are properly “bled”.

Suitable performance-related products are acceptable.

5-7 days after application of the Bitumen Membrane, thoroughly clean the surface of the membrane and apply 2 coats of Safeguard Bitumen Aluminium paint to the membrane using a brush, roller or spray.

Equivalent products are acceptable.

Thoroughly clean and prepare the surface, removing all laitance, dust, dirt, grime and grease.

Apply one coat of solvent-based Bitumen Primer to the surface ensuring full coverage without any “ponding” of primer on the surface.

Allow to dry and heat-fuse one layer of 4mm APP single re-inforced Bitumen Membrane to the primed surface, lapping all side walls and dressing into and around outlets and upstands.

Provide 100mm side laps and 150mm end laps to adjoining rolls of membrane, ensuring that laps are properly “bled”.

5-7 days after application of the Bitumen Membrane, thoroughly clean the surface of the membrane and apply 2 coats of Bitumen Aluminium paint to the membrane using a brush, roller or spray.

Thoroughly clean shower walls and floor, removing all loose dirt, mortar, grime and grease. Walls should not be plastered.

Apply a coat of Safeguard Latseal Slurry mixed with Bondaid to the walls and floor, embedding a non-woven polypropylene membrane into the slurry at all joints.

Allow to cure overnight and apply a further coat of Safeguard slurry to the entire area.

At the joint with the outlet, an expandable polyurethane sealant should be applied to cover both surfaces. This should be allowed to cure, together with the slurry before application of any tiles/mosaics.

Equivalent products are acceptable.

Thoroughly clean shower walls and floor, removing all loose dirt, mortar, grime and grease. Walls should not be plastered.

Apply a coat of cementitious waterproof slurry mixed with bonding liquid to the walls and floor, embedding a non-woven polypropylene membrane into the slurry at all joints.

Allow to cure overnight and apply a further coat of slurry to the entire area.

At the joint with the outlet, an expandable polyurethane sealant should be applied to cover both surfaces. This should be allowed to cure, together with the slurry before application of any tiles/mosaics.

Contact Us 011 7083603

Email techncal@safeguardchem.co.za